Optimizing confined-space sewer inspections with ASIO X drone

How SEH used the ASIO X to improve safety, efficiency, and data quality in pipe-in-a-pipe sewer inspections

Flight time

1 hour

Drone X

ASIO

Savings

$4K in labor and equipments

Industry

Water

Introduction

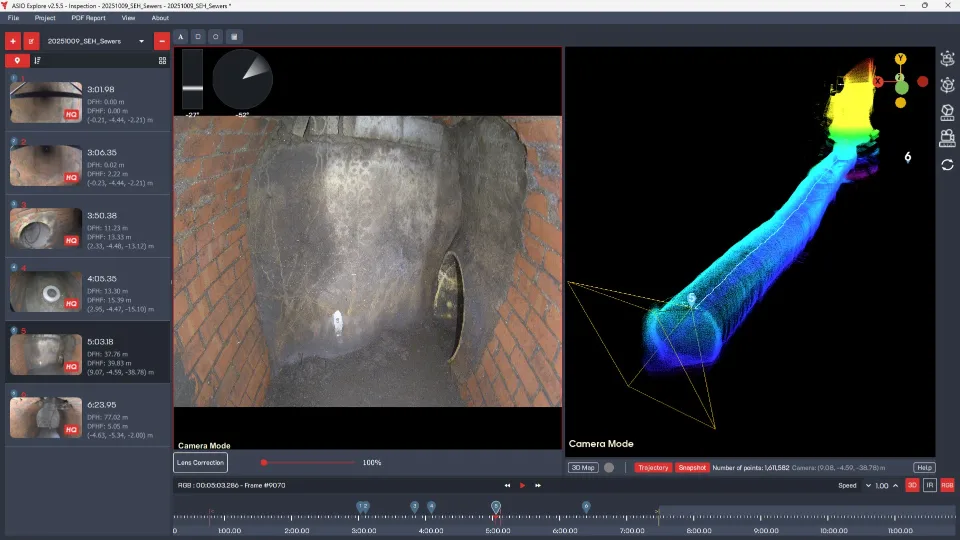

Short Elliott Hendrickson Inc. (SEH®), an employee-owned, multidisciplined professional services company with more than 900 engineers, architects, planners, scientists, and dedicated professionals, was engaged to assess the condition of a 148-linear-foot pipe-in-a-pipe structure. The asset consisted of a 60-inch brick egg-shaped sewer with significant debris accumulation.

Traditionally, this type of infrastructure is inspected via manned confined space entry. Due to safety risks, debris conditions, and cost, the client sought a safer and more efficient alternative. SEH selected the ASIO X drone to perform the inspection, eliminating the need for human entry while improving data quality and reducing overall inspection time.

Traditional inspection challenges

Prior inspections of this asset relied on full confined-space entry, requiring extensive preparation, equipment, and safety controls. Traditional methods of inspection, like closed-circuit television (CCTV) inspection, was not an option due to the amount of debris in the segment.

A typical inspection involved:

- A five-person trained crew

- Human entry into the pipe

- Confined-space safety systems, including tripod, harness, winch, and rescue equipment

- Atmospheric monitoring and ventilation

- Extensive personal protective equipment

- Handheld tools for measurement and visual documentation

This approach typically required a full day to complete and presented several challenges.

Safety risks

Data limitation

Logistics

Costs

The trigger for change

Due to debris conditions and confined-space risks, traditional inspection methods were inefficient and costly. The client sought an approach that would:

- Eliminate confined-space entry

- Avoid debris removal

- Improve visual documentation

- Reduce inspection time and labor costs

SEH proposed using the ASIO X drone to meet these objectives and introduce a safer inspection workflow for this asset.

Drone inspection setup

Team

- Lead drone pilot

- Project manager

Payloads

- RGB camera

- Gas sensors

- Infrared sensors

Environmental conditions

- Complete darkness

- Tight geometry within a 60-inch brick egg-shaped pipe

Preparation

- Risk assessment and mission planning

- Pilot training

Additional software or equipment

- None required

Solutions & Results

50%

reduction of the total inspection time

$4,000

reduction in labor and equipment setup costs

Execution:

The ASIO X completed the full 148-linear foot inspection in approximately one hour without issues. Key objectives included:

- Documenting interior pipe conditions

- Inspecting the bulkhead

- Providing live visibility to the client through screen sharing

With its ultrabright 40,000-lumen lighting system, stability, and maneuverability, the drone navigated the confined environment without requiring debris removal or human entry.

Results

- Time and Cost Savings:

- Approximately 4 hours saved compared to traditional methods

- Roughly $4,000 reduction in labor and equipment setup costs

- No confined-space setup required

- No personnel lowering or retrieval

- Safety Improvements: the ASIO X eliminated the need for human confined-space entry, removing exposure to:

- Toxic gases

- Trip and impact hazards

- Sharp debris

- Low-visibility conditions

- Data Quality Improvements

- Image and video quality rated significantly better than handheld cameras

- Improved clarity in low-light conditions

- More consistent documentation

- Live viewing enabled real-time client engagement

- Operational Benefits

- No asset downtime

- No debris removal required

- No additional contractors needed

- Real-time inspection visibility

Conclusion

Outlook & next steps

The success of this inspection reinforced SEH’s interest in expanding the use of ASIO X for confined and difficult-to-access environments. As Kevin Accola, Safety Director at SEH, noted:

“In safety, we first look for ways to eliminate hazards that employees may be exposed to. When elimination is possible, it is always preferred over relying on personal protective equipment. In this case, the ASIO X removed the need for confined-space entry altogether, eliminating the associated risks. Projects involving confined spaces should consider how this technology can replace human entry whenever feasible.”

Building on this project, SEH is preparing additional inspections for multiple clients and exploring new applications for ASIO X across the water and wastewater sector, including assets such as water towers. By integrating drone technology into inspection workflows, SEH continues to advance safer, more efficient approaches to evaluating critical infrastructure.

ELEVATE YOUR INSPECTION PROCESS

Talk to Our Team

Connect with our team for a firsthand look at the drone’s stability, assist functions, and maneuverability, ensuring all your questions are answered to experience our advanced technology.

View More Case Studies

Energy production

Discover How Flybotix’s ASIO Drone Reduced Inspection Time, Enhanced Safety, and Saved 60% on Costs for Leading Energy Provider Groupe-E.

Energy Production

Drone based inspection inside Oil Tanks allows 57% reduction in inspection time and saves days of asset uptime.

Mining

Enhance Safety and Efficiency in Roof and Mill Inspections at Baramin with Flybotix ASIO Drone.

Energy Production

How an Engineering Firm Halved Inspection Time, Saved 50% on Costs, and Improved Safety Using Flybotix's Advanced Technology